Resources

All resources

Promotional videos

Automated wafer-level testing of photonic integrated circuits - English

(May 18, 2023)

Flyers and pamphlets

Testing photonics and optical components for manufacturing, design and research challenges - English

(June 20, 2023)

Flyers and pamphlets

Testing photonics and optical components for manufacturing, design and research challenges - 中文

(June 20, 2023)

Flyers and pamphlets

Testing photonics and optical components for manufacturing, design and research challenges - 日本語

(June 20, 2023)

Promotional videos

Discover EXFO's comprehensive PIC testing solution - English

(May 18, 2023)

Brochures and catalogs

Optical testing solutions for manufacturing and R&D - English

(December 23, 2024)

Flyers and pamphlets

High-power continuously tunable laser series - English

(March 14, 2023)

Flyers and pamphlets

High-power continuously tunable laser series - Français

(March 14, 2023)

Flyers and pamphlets

High-power continuously tunable laser series - 中文

(March 14, 2023)

Flyers and pamphlets

High-power continuously tunable laser series - 日本語

(March 14, 2023)

Flyers and pamphlets

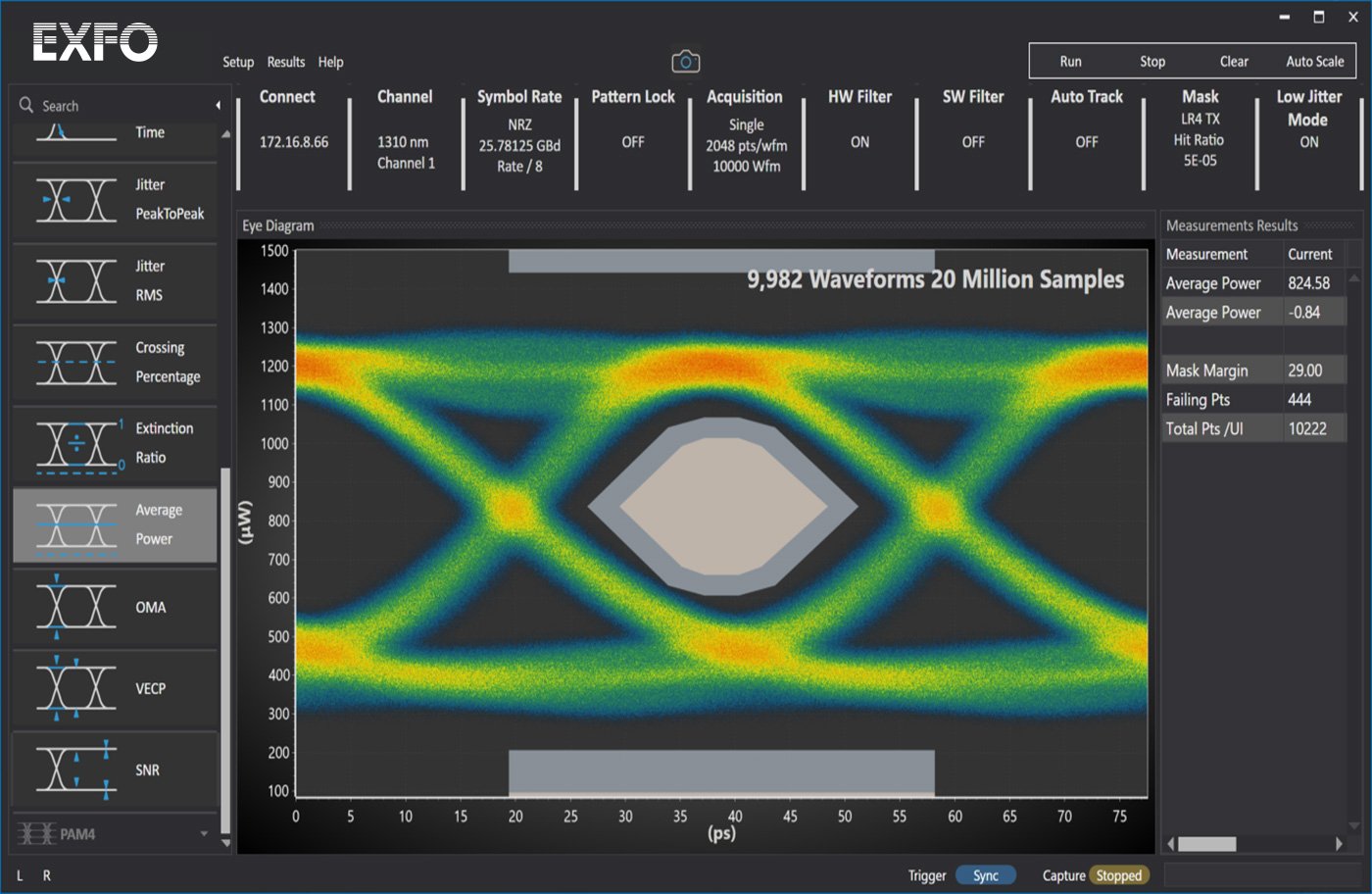

Leading-edge transmission testing up to 800G - English

(October 26, 2021)

Flyers and pamphlets

Leading-edge transmission testing up to 800G - 中文

(October 26, 2021)

Flyers and pamphlets

Leading-edge transmission testing up to 800G - 日本語

(October 26, 2021)

Spec sheet

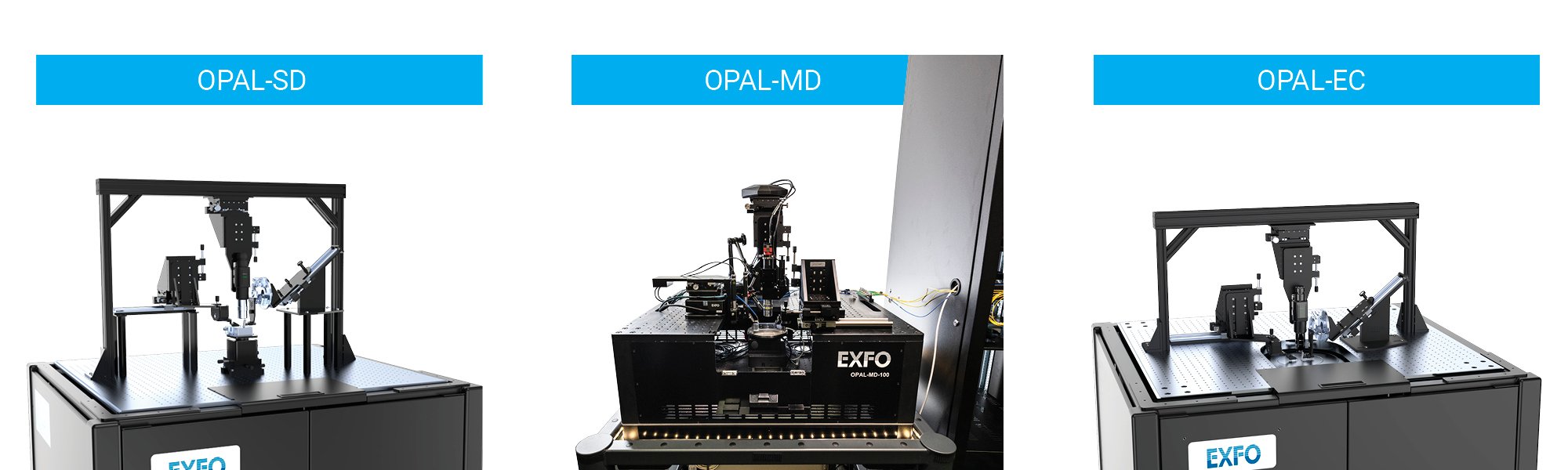

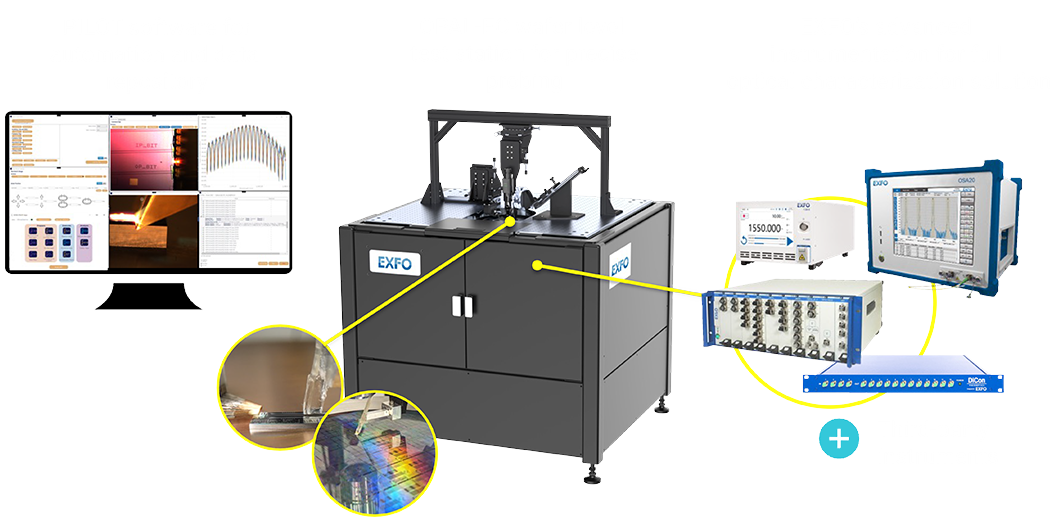

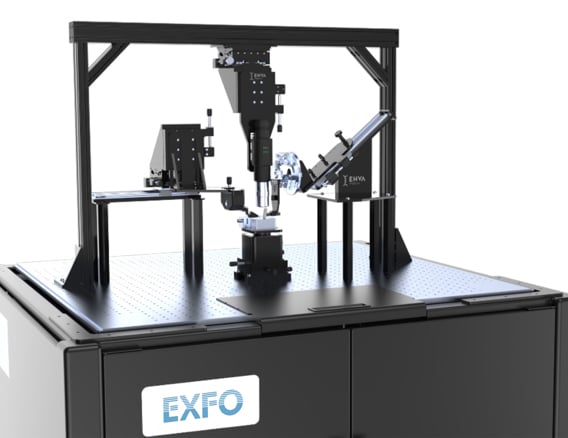

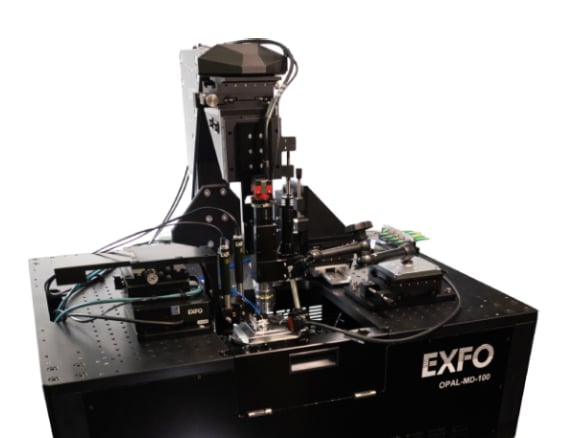

OPAL-EC – Edge-coupling wafer-level test station - English

(June 30, 2025)

Spec sheet

OPAL-EC – Edge-coupling wafer-level test station - Français

(June 30, 2025)

Spec sheet

OPAL-SD – Single-die testing - English

(June 30, 2025)

Spec sheet

OPAL-SD – Single-die testing - Français

(June 30, 2025)

Spec sheet

OPAL-SD – Single-die testing - 中文

(June 30, 2025)

Flyers and pamphlets

Optiwave and EXFO - Partners for automation in lab and manufacturing - English

(September 30, 2022)

Brochures and catalogs

Passive component characterization - English

(December 23, 2024)

Brochures and catalogs

Passive component characterization - 中文

(December 23, 2024)