Recursos

Todos los recursos

Videos promocionales

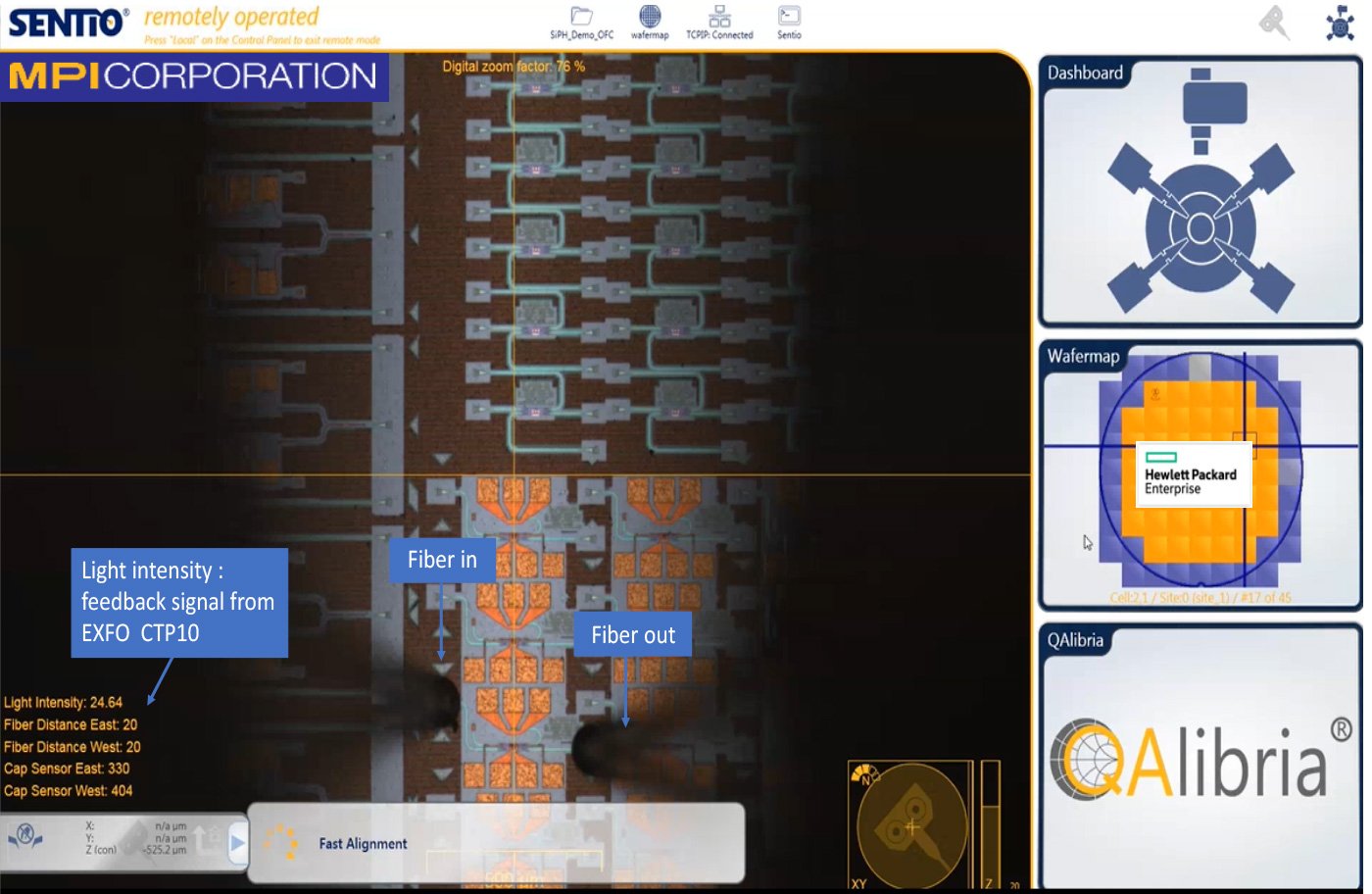

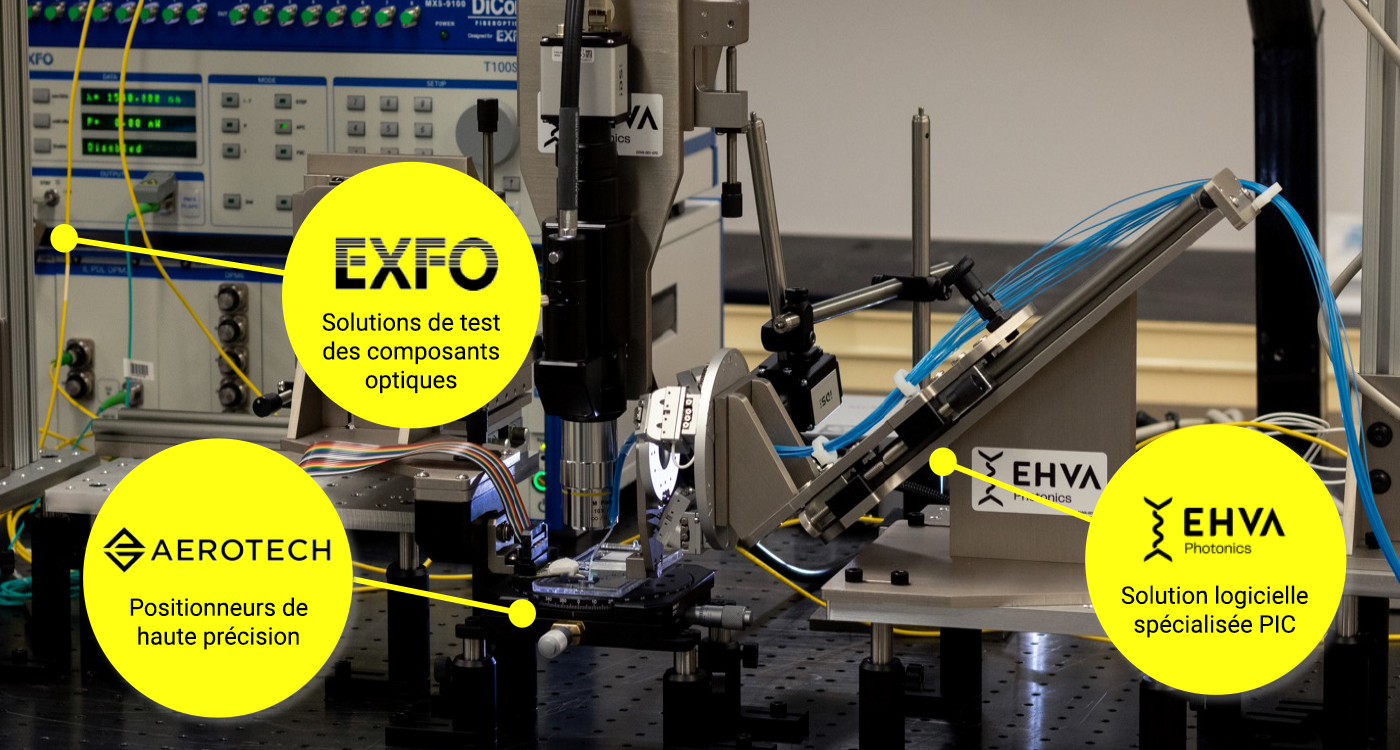

Accelerating photonics lab to fab with Aerotech, EHVA and EXFO - Español

(mayo 18, 2023)

Videos promocionales

Automated wafer-level testing of photonic integrated circuits - Español

(mayo 18, 2023)

Volantes y panfletos

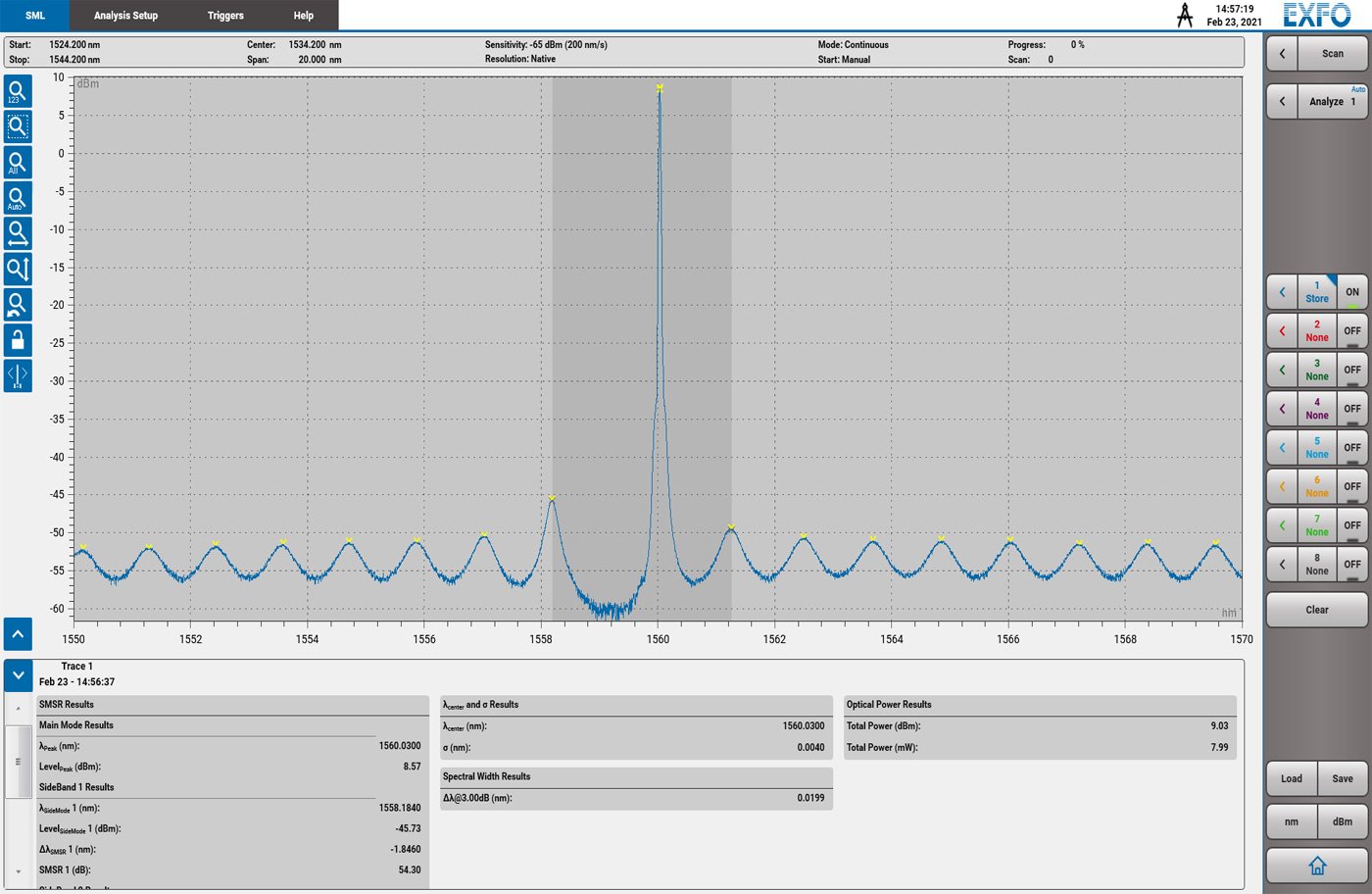

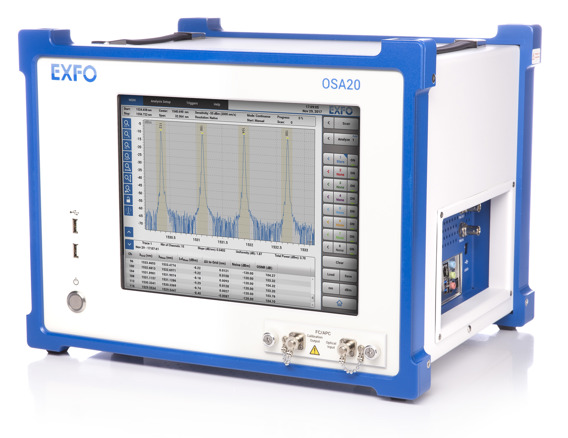

Component and PIC testing - English

(junio 20, 2023)

Volantes y panfletos

Component and PIC testing - 中文

(junio 20, 2023)

Volantes y panfletos

Component and PIC testing - 日本語

(junio 20, 2023)

Videos promocionales

Comprehensive testing of integrated photonics from lab to fab - Español

(septiembre 11, 2023)

Videos promocionales

Discover EXFO's comprehensive PIC testing solution - Español

(mayo 18, 2023)

Volantes y panfletos

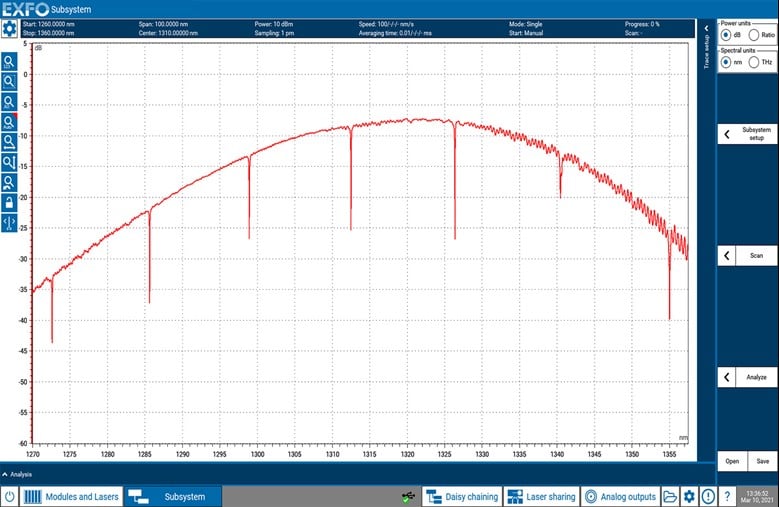

High-power continuously tunable laser series - English

(marzo 14, 2023)

Volantes y panfletos

High-power continuously tunable laser series - Français

(marzo 14, 2023)

Volantes y panfletos

High-power continuously tunable laser series - 中文

(marzo 14, 2023)

Volantes y panfletos

High-power continuously tunable laser series - 日本語

(marzo 14, 2023)

Folletos y catálogos

Optical testing solutions for manufacturing and R&D - English

(octubre 27, 2023)

Folletos y catálogos

Optical testing solutions for manufacturing and R&D - 中文

(octubre 27, 2023)

Folletos y catálogos

Optical testing solutions for manufacturing and R&D - 日本語

(octubre 27, 2023)

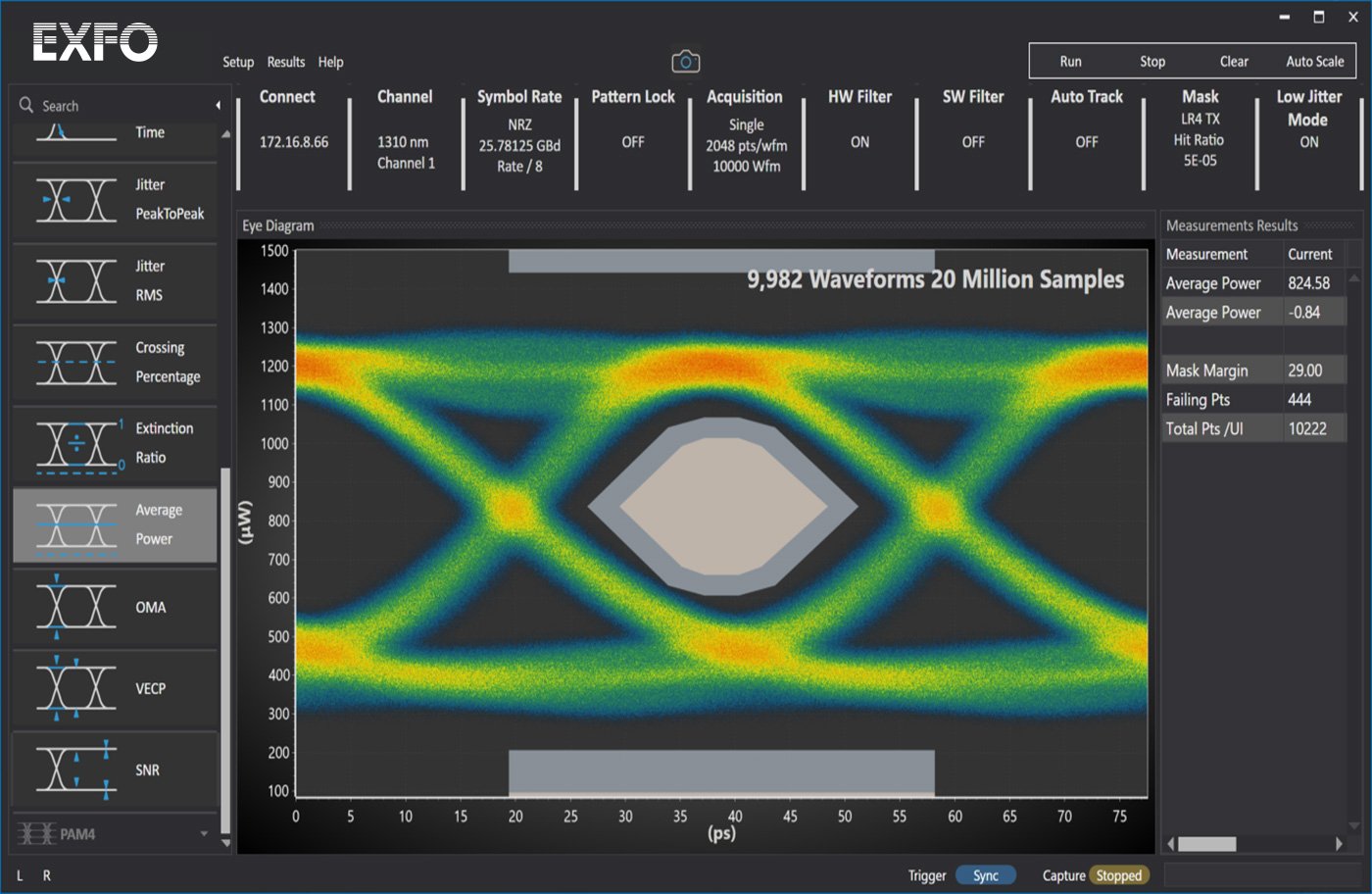

Volantes y panfletos

Leading-edge transmission testing up to 800G - English

(octubre 26, 2021)

Volantes y panfletos

Leading-edge transmission testing up to 800G - 中文

(octubre 26, 2021)

Volantes y panfletos

Leading-edge transmission testing up to 800G - 日本語

(octubre 26, 2021)

Hoja de especificaciones

OPAL-EC: edge-coupling wafer-level test station - English

(julio 19, 2024)

Hoja de especificaciones

OPAL-EC: edge-coupling wafer-level test station - 中文

(julio 19, 2024)

Hoja de especificaciones

OPAL-EC: edge-coupling wafer-level test station - 日本語

(julio 19, 2024)

Hoja de especificaciones

OPAL-EC: edge-coupling wafer-level test station - Français

(julio 19, 2024)

Hoja de especificaciones

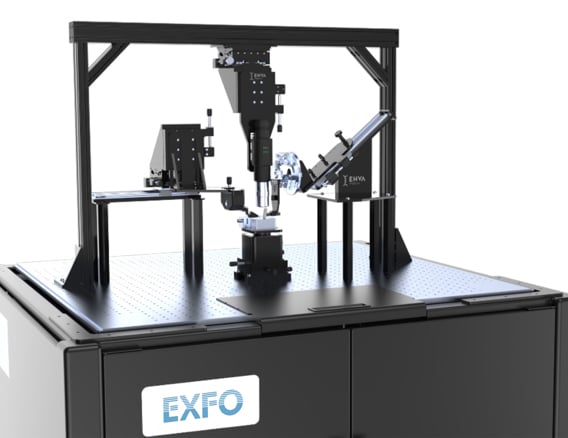

OPAL-SD - single-die testing - English

(abril 22, 2024)

Hoja de especificaciones

OPAL-SD - single-die testing - Français

(abril 22, 2024)

Hoja de especificaciones

OPAL-SD - single-die testing - 中文

(abril 22, 2024)