Small and Powerful: T&M Also Follows the Trend

Often I am asked about upcoming trends in the test and measurement world. While several microtrends depending on the test to be performed, the application and the user exist, there are two very important macrotrends.

- Compact, powerful and dedicated

- Intelligent and automated

In this day and age, almost everyone has had some sort of contact with a tablet, PC, or a powerful smartphone. These devices are ultra-performing, yet thin, elegant and robust with a long battery life. This is the de facto standard for personal devices. Inspired by this, the new breed of test equipment needs to respond to technicians’ reality: it is no longer just a matter of specifications and price, it’s also about units that allow technicians to do their job well, both fast and efficiently, while respecting a tighter and tighter budget. OPEX is, as previously discussed, a big issue in the telecom world, so cheaper equipment that does not get the job done quickly and efficiently is out of the question.

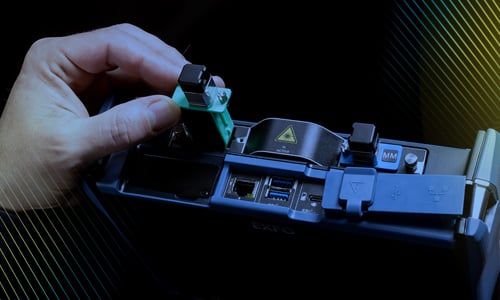

The most popular fiber optics test tool is an OTDR. Let’s apply the above concepts to the OTDR reality. The previous wave of small, cheap OTDR were handheld devices, similar in shape and form to a power meter. In both construction and high-volume testing, the size and resulting resolution of the screen is a huge limit. Zooming in and out is time-consuming, and leads to many errors during trace interpretation and analysis. The alternative is large, and often modular, platforms. While these certainly have their place among the technicians and applications we are referring to here, they are limiting because technicians already have to carry a myriad of tools around with them. As such, size, weight and robustness are key elements of consideration.

Next comes intelligence and automation. Training technicians is a luxury that many telcos can no longer afford. Setting up and configuring test equipment for a given job is a precious waste of time and money— especially in today’s context, where a single technician may have to employ several different types of configurations in a single day. Again, let’s apply this concept to the OTDR. The technician will have to decide which pulse width to use, which wavelength, and various other configurations. In addition, use of these settings requires the technician to be well-versed and familiar with the fiber under test, with sufficient knowledge about OTDR technology to optimize the various settings. Again, think tablet: click and go. This is what intelligence and automation means. In the case of semi-automation, otherwise known as “make-believe” automation, a manager arranges some test setups to simplify the technician’s job. This is again dependent on the need for the manager to know exactly what will happen in the field all the time. This does not represent dynamic adaptation, or intelligence and automation. What we are really pointing to here is dynamic adaptation of the unit, i.e., making it ready for anything that the technician or the field can throw at it.

Compact OTDR does exist. Indeed, OTDR comes in all types and variants: powerful, compact, inexpensive, intelligent, and/or simple. But, as of yet, these variants are not all available within a single unit. This is however, the ultimate goal and outcome of the current trend, and will be soon be applied to the most universal fiber optics test tool.