Maximizing the Long-Term Performance of Your OTDR/iOLM by Using APC Connectors

Optimizing the performance of an OTDR and the iOLM software application starts with low reflectance, as higher reflectance tends to stretch the dead zones. When testing an FTTx network, the impact of reflectance on performance is even greater, because of the large loss associated with a splitter. Contrary to UPC connectors, APC connectors usually maintain low reflectance—even when they are dirty or worn—which ensures optimum testing performance.

OTDRs are designed to deal with high reflectance on the network; however, if high reflectance is always present at the OTDR connector, performance will suffer for all measurements, even on APC-only links.

Impact of Reflectance on Attenuation Dead Zones

The attenuation dead zone is a specification that indicates the distance required, after a reflection, for the OTDR signal to return to the fiber backscatter level within less than 0.5 dB error. Both the receiver electronics and photodetector contribute to the recovery zone after a reflection.

In OTDR specification sheets, the attenuation dead zone is normally given for good-to-excellent reflectance conditions (–45 dB, –55 dB and even –65 dB, depending on OTDR manufacturers). It is well known that the reflectance level has a direct impact on OTDR dead zones, which will stretch longer as reflectance grows. This is due to the fact that connector reflectance can be many orders of magnitude greater than the backscatter signal level that is measured by an OTDR.

A good UPC connector with a reflectance of –55 dB produces a peak signal that is 100 times stronger than fiber backscattering with a 5 ns pulse (approximately –75 dB at 1550 nm). A bad UPC connector (typical reflectance from –45 to –25 dB) produces a peak signal that is 1000 to 100 000 times stronger than the fiber backscattering. With such a large range of reflectance-to-backscatter ratio, it is not surprising that the attenuation dead zone is highly dependent on connector reflectance.

Impact of Reflectance on PON Dead Zones

The definition of a PON dead zone is very similar to that of an attenuation dead zone, except that it applies for an event that has a significant loss value (whereas the attenuation dead zone normally applies to an event with negligible loss). Like the attenuation dead zone, the PON dead zone is defined as the distance for which the OTDR signal reaches the backscatter level within less than 0.5 dB error.

Let’s consider the example of a 1:32 splitter. The nominal loss of such a splitter is around 16 dB. Assuming that a 50 ns pulse is used to test the splitter, the backscatter level is –65 dB before the splitter, and –97 dB after the splitter (since the OTDR test signal travels back and forth through the splitter, the backscatter level after the splitter is 32 dB lower than before). A –45 dB reflectance is 2 000 000 times larger than the backscatter level after the splitter, which is huge. Significant time will be required for the OTDR detector to “recover” to backscatter level after a –45 dB reflectance. Obviously, things get even worse for reflectance higher than –45 dB.

Connector Reflectance: APC vs. UPC

As we have seen, the PON dead zone increases dramatically when strong reflectance precedes a splitter with large loss. Brand-new, clean UPC connectors have a good reflectance level (typically below –55 dB). However, as soon as they are worn or even just not perfectly clean, they tend to produce significantly larger reflectance. For instance, a dirty connector can generate a reflectance that is 1000 times larger than when it is clean.

In opposition, APC connectors, with their built-in angled ferrules, are fundamentally very robust against reflectance. Even when worn or dirty, they still maintain a decent reflectance level (typically better than –50 dB).

Impact of Reflectance on Measurements

When strong reflectance is present on a link between the OTDR and the splitter, a longer PON dead zone will occur. This longer PON dead zone will limit the ability to discriminate elements that are close to the splitter. In the example given below, three events (labeled 1, 2 and 3) are merged together in the presence of strong reflectance.

Reducing the Cost of Ownership

A worn or dirty connector on a test instrument is never desirable. Both UPC and APC connectors will suffer from excess loss when worn or dirty. The excess loss will force the OTDR user to select larger pulses to test a network. With excess loss of 1 or 2 dB, it is still possible to operate the OTDR and get good results. However, reflectance is a different story.

When testing an FTTx network, it is important to avoid any unnecessary reflectance. An OTDR with a damaged UPC connector becomes virtually useless for testing short FTTx networks. On the other hand, a slightly damaged APC connector (e.g., damage inducing excess loss of 1 or 2 dB) is still functional because the reflectance will remain in the –50 dB range.

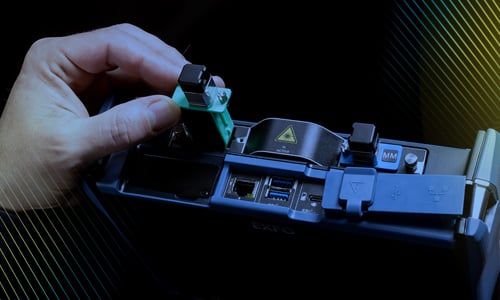

Overall, an OTDR with an APC connector will require less frequent repairs (connector change) to deliver constant measurements and reliable testing. In addition, a network using UPC connectors can easily be tested using a hybrid test jumper (APC at the OTDR/iOLM end, and UPC at the network end). This is why EXFO strongly recommends the use of APC connectors for OTDRs, making it mandatory for the iOLM application.