From Down and Dirty to Fresh and Clean

The EXFO team would like to wish you a happy new year! Why not start 2013 with a resolution to improve your fiber network?

Cleaning fiber connectors might seem like a trivial task, but its impact on overall network performance is immediate. The adverse effects of scratched, dirty or defective connectors on the network will tend to grow as fiber networks expand to homes and other premises.

To keep your fiber operating optimally, connectors should be cleaned, inspected and qualified.

Whether you choose to go with dry cleaning or hybrid cleaning, the goal remains to implement a technique that cleans a connector right the first time. This will lower costs, reduce worker frustration and encourage troubleshooting using OTDRs or other tools.

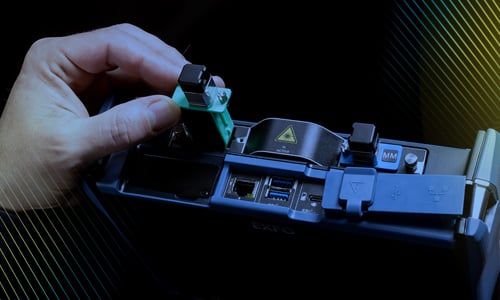

Beyond physically cleaning connectors, you can take advantage of the process to inspect connectors using the increasingly popular handheld inspection probes.

Connector qualification relies on industry standards like BS EN 61300-3-35, which is used to define the connector face areas that are of critical interest, i.e., the core, cladding, adhesive and contact.

Preventive maintenance instead of repairs

The best way for a technician to handle connector contamination is to implement a strict cleaning and inspection technique as well as learn to recognize the effects of cleaning on test results. In short, always inspect and clean prior to connecting. Failing to inspect will only lead to repeat jobs.

Using these best practices at every step of the connector-handling process reduces unnecessary truck rolls and delays, and, as always, the bottom line.