Copper Pairs: Making the Jump from POTS to Broadband Services

The original intent of this blog was to list and explain the major pitfalls of copper testing. When it was clear that the list had become way too long, I decided to take a different approach, as reflected in the above title.

Typically, in today’s networks, the greatest percentage of faults occurs in the last mile. As such, extra care should be taken at this stage, at which OPEX, extra truck rolls, maintenance contracts and more, can really take a toll.

In the past, little effort was made to get a plain old telephone service (POTS) line to work; however, a broadband service requires a very clean pair. By very clean, see the descriptions in the list below:

- No load coils or bridged taps

- Pairs must be free of DC faults, for instance, a crossed battery

- Shorts or grounds showing less than 20M ohms must be identified and repaired

- Any serial resistance or split pairs must be identified and resolved

- Pairs must be balanced

- Longitudinal balance must be greater than 60 dB

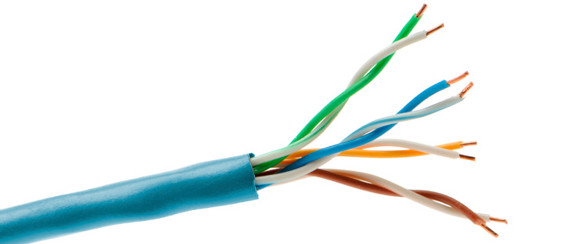

This means, among other things, that any spliced pairs in a splice box that were pushed back in for the POTS must now be methodically twisted when put back together in order to keep the integrity of the complete binder group.

In today’s techy world, sources of electromagnetic interference are now numerous and cause multitudes of problems. The twisted pair carries broadband, but unfortunately, it is also a noise antenna. Any unfiltered household appliances, including AM radio stations, HAM radio, or competing technologies, are likely to cause problems. All bridged taps must be located and cleared.

Bonding and grounding is also of key importance. A continuous bonding of the cable shield must be completed to mitigate noise as much as possible. A thorough set of metallic tests must be run in order to verify that the pair is clean. If it is not, the source of the parasitic noise must be identified.

Voltage, capacitance and resistance tests must also be run. TDR traces are not particularly easy to interpret, so you should already have a good idea as to how the pair looks (metallically speaking) before running it.

New methods of testing introduced by EXFO, including those found in the Pair Detective and Fault Mapper, make the detection and identification of these faults a quick and easy task.