The Benefits of Remotely Operated OTDRs for Submarine Cable Deployment, Fiber Monitoring and Restoration

For network operators, waterways represent a cost-effective alternative to terrestrial routes when a path has to be constructed for linking two cities or any two landing points—either a festoon-style link connecting two points along the coast, a connection from an island to the mainland or a connection from a platform at sea to the continent. Such cables remain relatively close to the coast and rest at seabed levels, typically a few meters to a few hundred meters deep. Keeping these cables free from any major defect becomes challenging due to human activities such as fishing, trawling and anchoring. The worst locations are heavy traffic areas like channels and straits.

As illustrated in figure 1, most cable damages occur close to the coast and can be repaired quickly with an optimized selection of equipment and resources. Despite the availability of a significant quantity of the effective technologies and tools, the repair process of a cable remains quite long, stretching from days to weeks in some cases. Although the solution presented here will not dramatically improve these figures on its own, it can be used in association with these other technologies in order to cut the overall time-to-repair, likely reducing the manpower involved mainly for optical testing and, in some cases, even increase the number of situations where preventive actions can be conducted before the whole cable is lost.

Unrepeated Links and the Evolution of Submarine Cable Design

Unrepeated submarine links, by design, do not require copper sheath nor power feed equipment (PFE); this creates a situation where fault localization techniques based on shunt fault cannot be used. Nevertheless, most cables are comprised of electric-conductive material, copper sheath or tape, to propagate high-voltage injection of tones in order to track the cable route from the vessel and help locate the actual point of failure used in a submarine remotely operated vehicle (ROV) or by divers in shallow waters. OTDRs are likely to become the more common means of measuring optical continuity in repeater-less cable systems, due to the intrinsic nature of cable designs for this application.

Remote Stations and Monitoring Requirements

It may often be advantageous to bring the cable back on the shore to optically regenerate the signals, and this is particularly true on coastal routes. Remote stations are subject to damage either from thieves or vandals, especially in cases where the cables cannot be totally hidden and protected. A remotely accessible optical test instrument such as an onsite OTDR, which can continuously check one or many fibers in one or many cables, can make a huge difference in terms of reaction and restoration time in case of malicious attacks. Not only must this equipment be able to detect and determine the sheath length of the fault, but it must also be able to quickly alert one or many individuals that a cable outage has occurred—or even better, is soon to occur. EXFO’s Fiber Guardian is a test and network maintenance solution that can be deployed at strategic points of the submarine cable network, providing direct and remote access to fiber condition from virtually anywhere.

Typical Implementation

In the scenario below (two fictive cable routes), there are three landing points: Rome, Napoli and Palermo. The Rome to Napoli section is approximately 300 km long and can be managed with a repeater-less system. The Napoli to Palermo section is less than 400 km long and can also be deployed without the use of repeaters. Test units will be located at each terminal station, incorporating a 1 x n optical switch for path switching. In an ideal case, one fiber per cable is reserved to be connected directly to the test unit through the optical distribution frame (ODF). It is identified as the “dark” fiber. All other live fibers can be connected to the test unit through a multiplexer (FWDM) to avoid the need to go onsite when a test path must be created to any fiber of the cable; live fiber testing can be done while transmission signals are “on” or “off”.

In this example, the entire cable can be tested from both sides. This requires the OTDR to use a longer pulse width and test durations of about 1 minute per fiber for measuring a fiber end/cut at 40 dB attenuation. The dark fiber can be used to monitor the cable and in case it is cut, the cable length at which the fiber is broken can be measured with a precision that will vary according to distance from the unit, as per the values presented in table 1.

In the above implementation, the dark fiber is tested at 1550 nm in one direction and at 1625 nm in the other, because one unit cannot test much beyond 40 dB attenuation. The graph below presents a baseline trace taken with EXFO’s FTB-7600E OTDR module over a submarine link of about 300 km. Taking into account the injection loss induced by the optical switch and jumper cable, the graph clearly shows the capability to cover a length of more than 200 km from a single-ended OTDR instrument.

Rejection of the 1550 nm OTDR signal on the opposite side enables testing of the same fiber from both sides—whether the test unit on the other side is testing or not. For live fibers possibly carrying traffic, the test is performed at 1625 nm from both sides; in this case, measurements therefore should be taken by a single operator or application, so that the test runs from one side at a time. Obviously, for links of up to 200 km, single-ended testing is possible, but without the resolution that dual-ended testing would provide.

|

Fiber length to fault (km) |

1.25 |

10 |

40 |

200 |

|

Fault location uncertainty (typ.) m ± |

1 |

2 |

5 |

18 |

Although the measurement range performance can be impaired when testing live fiber compared to dark, due to the increased level of Raman-generated spontaneous noise scattered back to the OTDR wavelength band, there is a major advantage to being able to test all fibers from the station without having to send anyone onsite for optical connection; this way, measurements can be performed totally remotely, from the ship, the network operation center or elsewhere.

The fault location uncertainty figures in Table 1 assume the individual-fiber-to-cable-length (scale factor) is known and specified as part of the OTDR test parameters. This factor must be calibrated when the cable is constructed; otherwise it can be done when the cable is actually installed, so that the OTDR’s reach from start to end of each of the cable sections is referenced to a location on the ship route, and then by computation on the seabed. For submarine routes, an important difference may exist between the actual cable position on the seabed and the position of the ship where the cable touches water. Computation of ship route and actual cable position when it touches down (in latitude, longitude and depth) represents a critical aspect—to some extent a precondition—for the valuable use of any optical-based fault localization method.

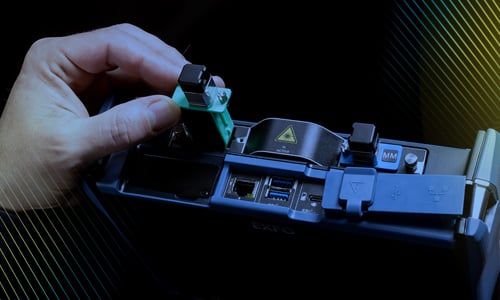

Remote Connectivity Enables Effective Cable Testing

Once installed and hooked to the cable to be tested or monitored, the unit is connected to a LAN/WAN over Ethernet/TCP/IP through a Web server running directly on the unit. This enables the NOC or remote users to access the unit for configuration or testing purposes from virtually anywhere. If a monitoring routine on one or many fibers is started, users can receive programmed alerts, should the fiber(s) degrade or break. Those alerts can be short-messaging service (SMS) text messages sent from a modem on the unit directly to any type of mobile phone for immediate notification—within seconds from the time the unit detects fault conditions. Testing and configuration functions are accessible through a Web browser. The unit can be interfaced over SNMP to provide integration with network management or supervision systems.

Verification and Measurements When Cable Is Laid Down

As the test unit is typically equipped with an internal optical switch unit, it can test all the fibers while the cable ship is laying down the cable. From the terminal station to where the cable hits water, monitoring on all fibers can be done to ensure the process can be stopped and cable integrity verified, if cable conditions, from an optical-quality standpoint, change significantly. Fault detection thresholds as small as 0.05 dB can be applied while the cable is being buried. Access to fault information such as raw OTDR measurements can be gained from the ship or from the network operation center, using a simple Web browser.

Typical Remote OTDR Test and Monitoring Applications in Submarine Cable Systems

As previously discussed, an OTDR and optical switch installed at the terminal station of a cable can serve numerous needs and applications.

- Monitor a cable of up to 200 km and alert one or many team members of possible issues with the cable

- Help measure actual fiber to cable length “scale factor” if cable spans are spliced on the cable ship before immersion

- When supporting a repair crew, test splice quality in real time from the terminal station

- Test a fiber that was dark for a long time prior to service activation

- Measure more accurately the time-to-repair and decrease dependence on repair crews

- Speed up the reaction in case of malicious attacks on coastal cables

Outer-Diameter Sensory Fibers for Early Warning of Cable Stress

The cost of submarine cable repairs, the huge manpower involved and the number of such events worldwide will force operators to look into new ways to reduce their submarine cable installation and maintenance expenses. The OTDR surveillance of a few sensory fibers in the outer sheath of the cable—e.g., one per quadrant—would provide early warnings for possible cable intrusion in a more preventive approach. The health and condition of these fibers would assuredly be representative of the overall cable condition. In such a case, choosing commercially available remote test and monitoring equipment based on OTDR technology traditionally developed for terrestrial applications could serve even better.

Conclusion

This article examined the application and use of traditional OTDRs for remote control of submarine cable installation and fault management-related activities and presented an out-of-the-box monitoring and remote test solution that can be installed at the terminal stations of unrepeated links of up to 400 km. Moreover, for links equipped with repeaters, the solution tests up to the first repeater or up to 250 km if a fiber is passively dedicated to OTDR-testing purposes. Also, an attenuation decrease of a few tenths of a decibel can be detected and located and cuts can be identified with meter-level accuracy in terms of cable/fiber sheath length.