The three essential test tools required when deploying xWDM passive fiber networks

When you send your technicians to reliably install or troubleshoot xWDM links (CWDM or DWDM) within your high-bandwidth network, make sure they are equipped with the three essentials tools they will need to reduce installation errors and minimize further service calls: fiber inspection probes, OTDRs and combined Ethernet and CPRI testers. These test solutions will enable your technicians to skillfully navigate the most common installation and maintenance challenges in xWDM passive networking.

How xWDM is enabling C-RAN and fiber deep

xWDM passive technology is gaining traction in two distinct markets: C-RAN (centralized radio access network) with next-generation fronthaul mobile networks and fiber deep infrastructure for business services. xWDM passive networks will enable service providers and MSOs (multi-service operators) to increase bandwidth, improve reliability and reduce power consumption. CWDM increases bandwidth by 8-18x over previous network architectures through the multiplexing of multiple transmission wavelengths onto one fiber with each wavelength carrying a distinct data flow. DWDM supports higher speed links and typically 40 channels and can scale to an even higher bandwidth option—up to 80 channels.

As mobile network operators (MNOs) expand services, increase the number of antennas per cell site, and plan the imminent transition to 5G, they are installing fiber-to-the-antenna (FTTA) and embracing C-RAN which moves the mobile baseband unit (BBU) to a centralized location (such as data centers or central offices) that serves multiple towers. CWDM passive fiber is an ideal link between BBUs and the antennas, offering a clear demarcation point while lowering CAPEX and OPEX cost, delivering improved scalability and providing a seamless roadmap to the even higher performant DWDM.

Cable broadband providers rolling out a wide array of business services are embracing an initiative called fiber deep, which brings fiber closer to customers in the hybrid fiber coaxial (HFC) network. Extending fiber deeper into the network enables an architecture called Remote PHY (R-PHY), which moves the physical layer (PHY) of the cable modem termination system (CMTS) chassis out of the crowded CATV head-end to the edge of the HFC network. DWDM passive fiber has become the leading technology chosen to connect the head-end to the R-PHY nodes.

Whether your interest is in FTTA or fiber deep, xWDM offers a cost-effective solution for high-bandwidth, scalable networking without the necessity for costly active equipment in the field.

Challenges in xWDM networks

Teams that are new to xWDM fiber networking will encounter several challenges that can complicate installing and maintaining xWDM infrastructures.

- Deployment of new fibers – Implementing C-RAN and R-PHY will require operators to install new fiber optic cables featuring xWDM optics. Installation of CWDM links (or DWDM upgrades) is complex and requires testing of a high number of channels. Companies new to xWDM don’t have the tools, skills or processes required for the job.

- More connection points and unfamiliar failure modes – Each xWDM wavelength is associated with a different customer or location. Each optical connection point within a fiber optic link is a potential point of failure. Research shows that 80% of link problems are caused by connector-related issues. The number one connector problem is cleanliness. Dirty connectors tend to generate a high reflection back to the transmitter, increasing insertion loss (IL), optical return loss (ORL) and bit error rates (BER). Technicians without proper diagnostic tools often make the mistake of swapping out dirty connectors instead of simply cleaning them. This can be an expensive habit, particularly for high-value components such as the SFP optical transceivers utilized in such applications. Dirty connectors in a fiber network running protocols at lower speeds such as 1Gbps, may not exhibit any issues but may become problematic when migrating to higher speed protocols like 10Gbps or when migrating to 5G networks.

- CPRI and OBSAI – There are several challenges related to CPRI and OBSAI (Open Base Station Architecture Initiative), which are technologies that enable mobile RF signals to be transmitted over fiber. Technicians need to be able to diagnose communication issues between the remote radio head (RRH) and the BBU equipment. In some cases, SFPs inside the RRH may not be properly mated or may simply be faulty, thus preventing the flow of data. The technician must also validate that the speed setting on the RRH and the BBU match. If they are set to different speeds, the two sides will not properly synchronize. Furthermore, the technician has to make sure that the correct type of SFP is installed. In xWDM networks, each BBU/RRH link operates at a specific wavelength. If the SFP’s wavelength in the RRH does not match the SFP’s wavelength in the BBU, the communication link will not be established. It is therefore critical that mobile technicians and contractors have the proper test equipment to validate the CPRI or OBSAI communication link from the BBU location to the RRH during the mobile network installation phase.

- Validation of the entire link – Remote PHY and business services initiatives can achieve an exponential increase in bandwidth by adding xWDM channels to existing fiber infrastructures using multiplexers (MUX) and de-multiplexers (DEMUX). Because such devices act as filters for each wavelength, legacy 1310/ 1550 nm OTDRs are unable to test newer CWDM and DWDM wavelengths that pass through these filters. This creates a new challenge to verify, characterize or troubleshoot a specific channel without bringing down the entire system. In-service testing minimizes downtime and maximizes the customer’s quality of experience (QoE).

Preparing for the CWDM/DWDM era

To meet the above challenges, you need the ability to test three parameters of the link. Using the instruments outlined below will give your technicians the highest probability of completing a zero-defect installation or fixing an issue more rapidly. Ultimately, these tools will pay for themselves many times over by improving efficiency.

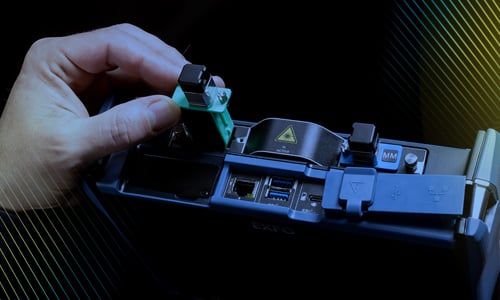

- Fiber inspection probe (FIP) – The pocket-sized, hand-held FIP is a critical tool used by technicians at the top of a tower, in the BBU hotel or at optical nodes. It’s used to inspect all optical connectors and SFPs. EXFO’s FIP-435B is a fully automated one-click fiber inspection solution designed for one-handed operation, with a simple LED pass/fail indicator and WiFi interface to a smartphone testing application.

- xWDM optical time-domain reflectometer (OTDR) – These instruments characterize an optical fiber utilizing a single-ended approach, allowing a single technician to test from an easy-to-access location such as the BBU hotel or from head-ends. By using EXFO’s TK-1-740C-xWDM OTDR, the wavelengths of the OTDR match the wavelengths of the SFPs so you can accurately test each channel individually through the filters until you have validated all the active paths over the fiber optic cable. All this can be done during the construction phase before the hand-off to ensure any potential problems are fixed prior to leaving the job site.

- Ethernet and CPRI tester– Whereas the OTDR tests the physical layer, the Ethernet tester verifies that Ethernet frames and Internet Protocol (IP) packets are being correctly transferred over the backbone network. The CPRI/OBSAI testing features will perform link communication validation as well as RF spectrum analysis over CPRI to accurately detect any RF interference issues during the commissioning phase. The CWDM OTDR, Ethernet tester and CPRI/OBSAI tests are combined into one compact unit, EXFO’s FTB-1/FTB-740Gv2 optical/Ethernet tester.

The FIP and all-in-one OTDR combos will help your team find and resolve issues before they leave the installation site, increasing turn-up success rates. They will help minimize latent failures and reduce the need to dispatch technicians to service or troubleshoot the fiber cable or Ethernet services. Getting it right the first time will help the organization meet its CAPEX and OPEX goals and ensure a trouble-free customer experience. With the suite of value-added test solutions listed above, your organization can proceed into the xWDM era with confidence.