Another Good Reason to Inspect Connectors after Cleaning

During regular visits to telecom rooms and central offices, it has come to our attention that technicians are more aware of the need to clean connectors than ever before. The issues related to dirty and/or damaged connectors have been well publicized, and are reputed to be the fiber network’s #1 enemy.

So, what about inspecting after cleaning...is it necessary? The answer is yes: inspection is necessary to guarantee that the cleaning job was done properly. But even still, there’s a lot more at work here than meets the eye. Let’s take a closer look...

Cleaning fiber-optic connectors requires proper fiber-optic-grade cleaning materials. Materials vary from optical-grade wipes to cassette cleaners. These elements of cleaning are often referred to as dry-cleaning. Although use of such tools to clean connectors will remove most, if not all contaminants, it could also attract new ones. Indeed, these tools may also add a static charge across a connector endface. During dry winter months and in air-conditioned areas, this static charge can cause significant interference with the connector cleaning process.

In simple terms, just as rubbing a balloon against your hair will make the balloon stick to walls, static charge buildup on connectors attracts charged particles to the connector endface. The static generated by rubbing an endface with a dry wipe acts as a magnet and attracts particulate and other contamination. This can effectively nullify the dry-cleaning process. Particles are drawn to the foremost part of the connector endface during mating and unmating. Since fiber-optic connectors are polished to have a radius endface with the fiber core at the center, static charge may cause particles to migrate to the optimal signal-blocking position. As such, fiber optic cleaning fluids are optimal for eliminating static charges as they neutralize the electrostatic charge at the connector endface. In addition, re-inspecting the endface―ideally with an autofocus and autocenter inspection probe―is required to avoid false positives.

Of course, when cleaning and inspecting it is important to cover both connectors on the jumpers, in addition to the connector behind the panel.

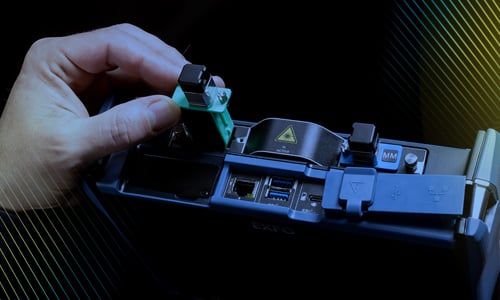

To find out how to transform the critical inspection step into a quick and simple one-step process that can be performed by technicians of any skill level, check out our FIP-430B, the first fully automated fiber inspection probe for the field.