保护OTDR的性能——从连接器开始

在现场,即使是最小的器件也可能会对性能产生很大的影响。对于OTDR来说,连接器是最为关键的器件之一。随着时间的推移,反复的连接和断开可能会造成磨损,从而导致损耗、测量结果不一致,甚至可能会导致成本高昂的故障停机。

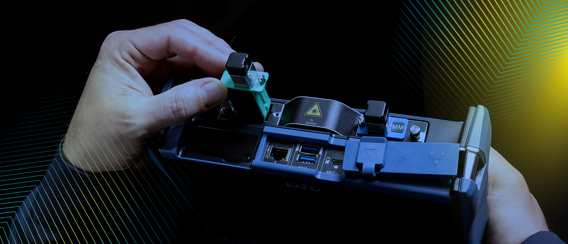

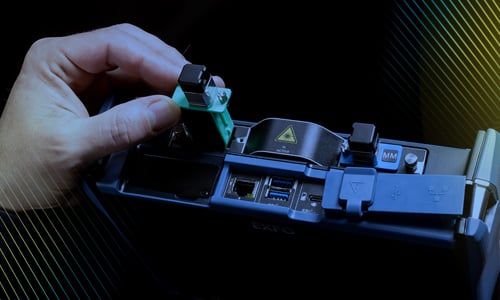

EXFO的专利Swap-Out (可替换)连接器是一项支持现场应用的专利技术,可直接解决这个问题。

Swap-Out连接器旨在让OTDR能够保持最高的精准度,使技术人员可以轻松更换磨损或损坏的连接器,而无需将设备寄到服务中心进行维修。这种方法不仅十分巧妙,而且非常简单,能够降低维护成本并保持测试工作流程的顺畅运行。

但这是否会影响到测试质量?其实完全不会。

我们最新的应用说明也证明了这一点。从动态范围和光回损(ORL)到盲区完整性,Swap-Out连接器都经受住了挑战,几乎不会对性能产生任何影响,这是因为它采用了精确的设计和先进的质量控制。事实上,我们的所有出厂动态范围规格都包含了连接器,以实现完全透明。

无论您是在管理大型现场团队还是在关键的环境中进行测试,Swap-Out连接器都能保护您的投资,同时确保每一步的测试都保持一致。

希望减少故障时间、加快维护速度并保持团队效率,同时又不影响测试质量?结果好不好,测试数据说明了一切。立即阅读完整的应用说明。