Resources

All resources

Spec sheet

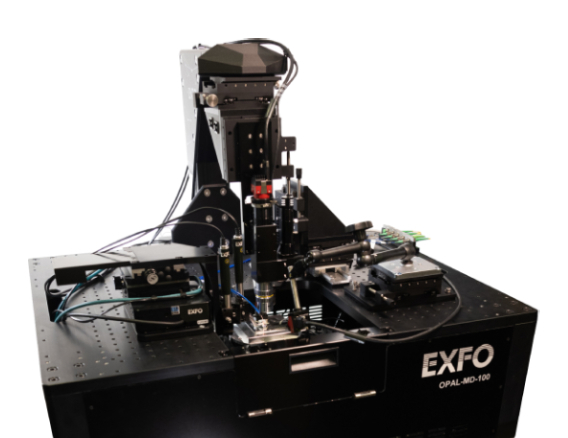

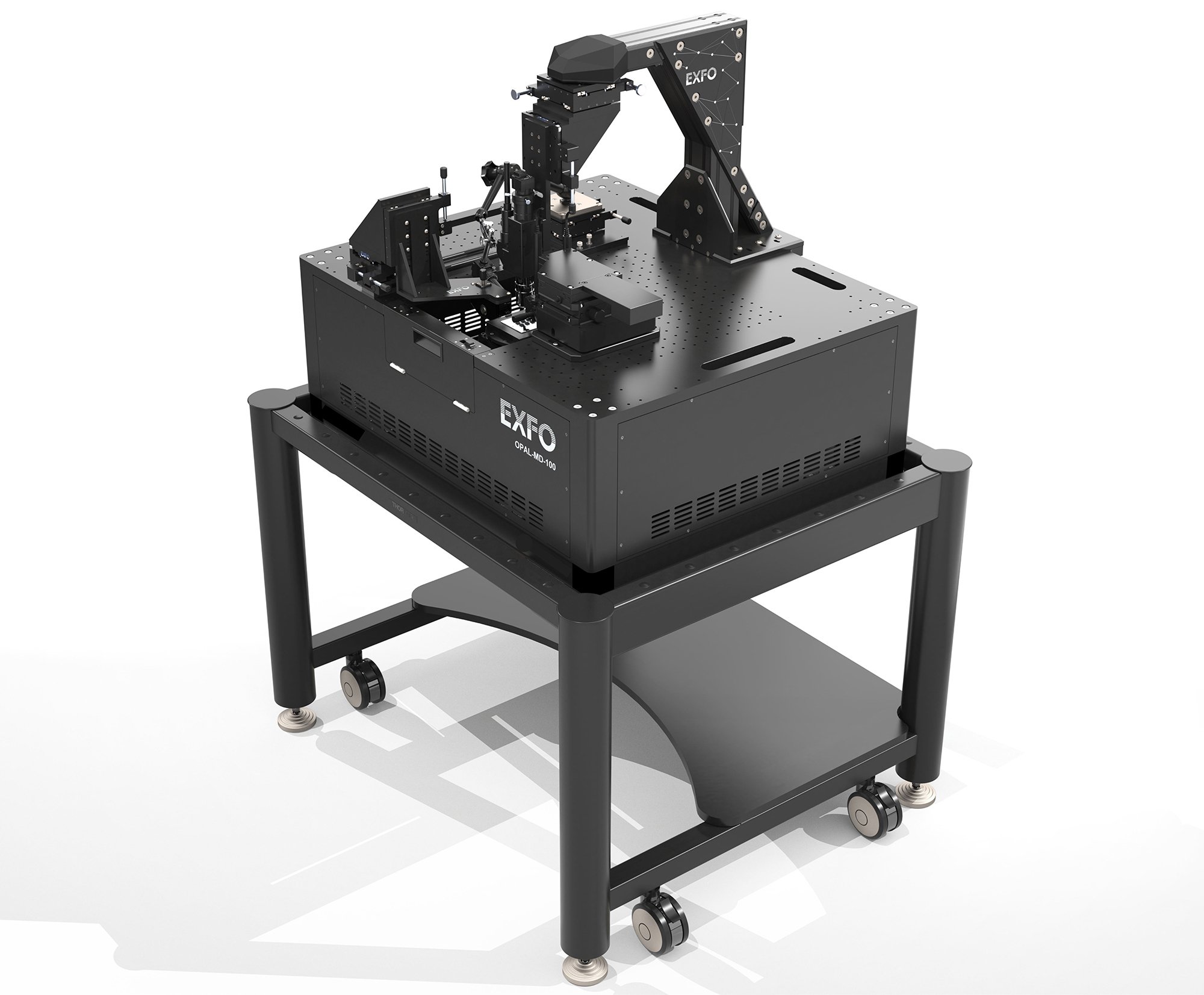

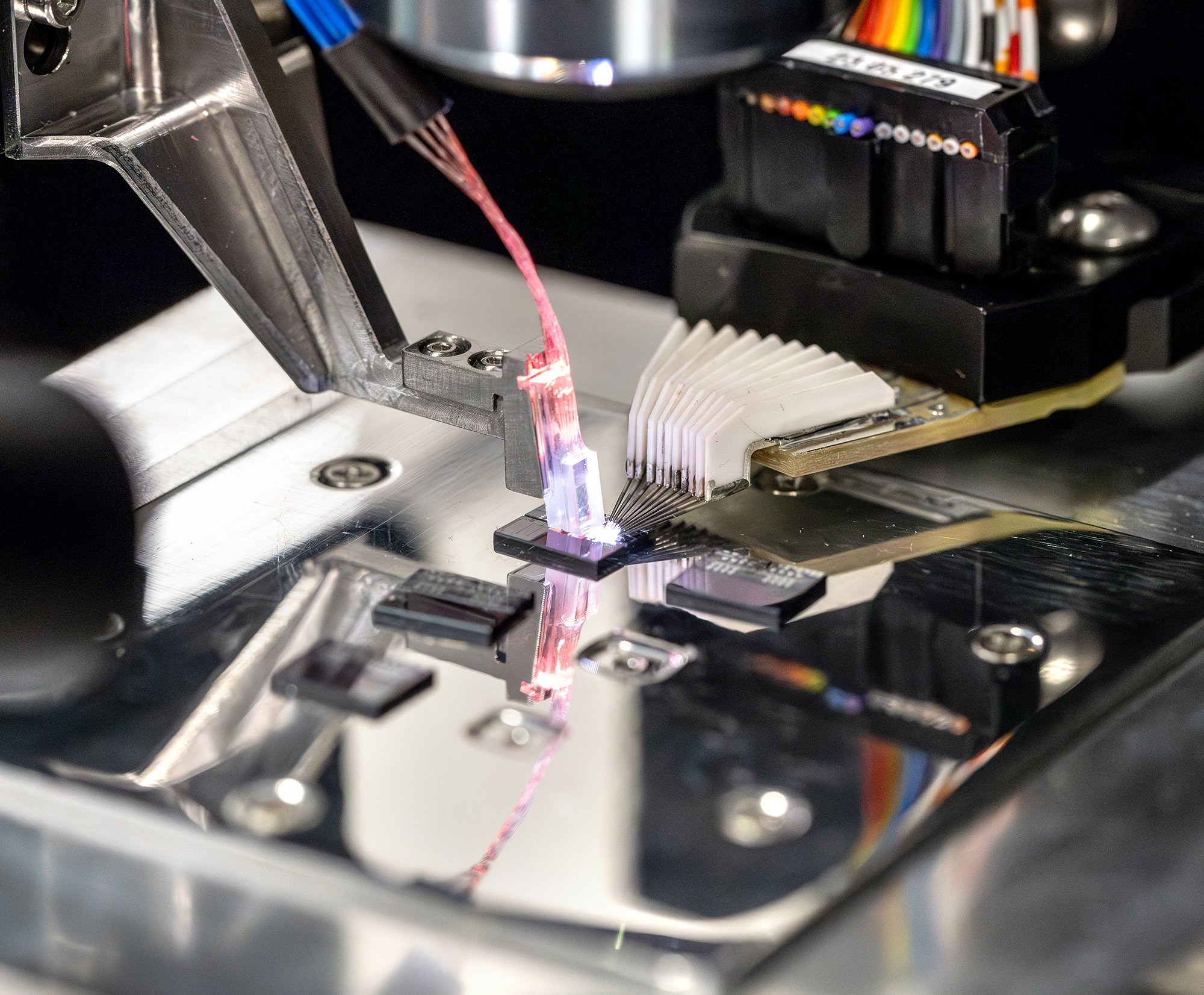

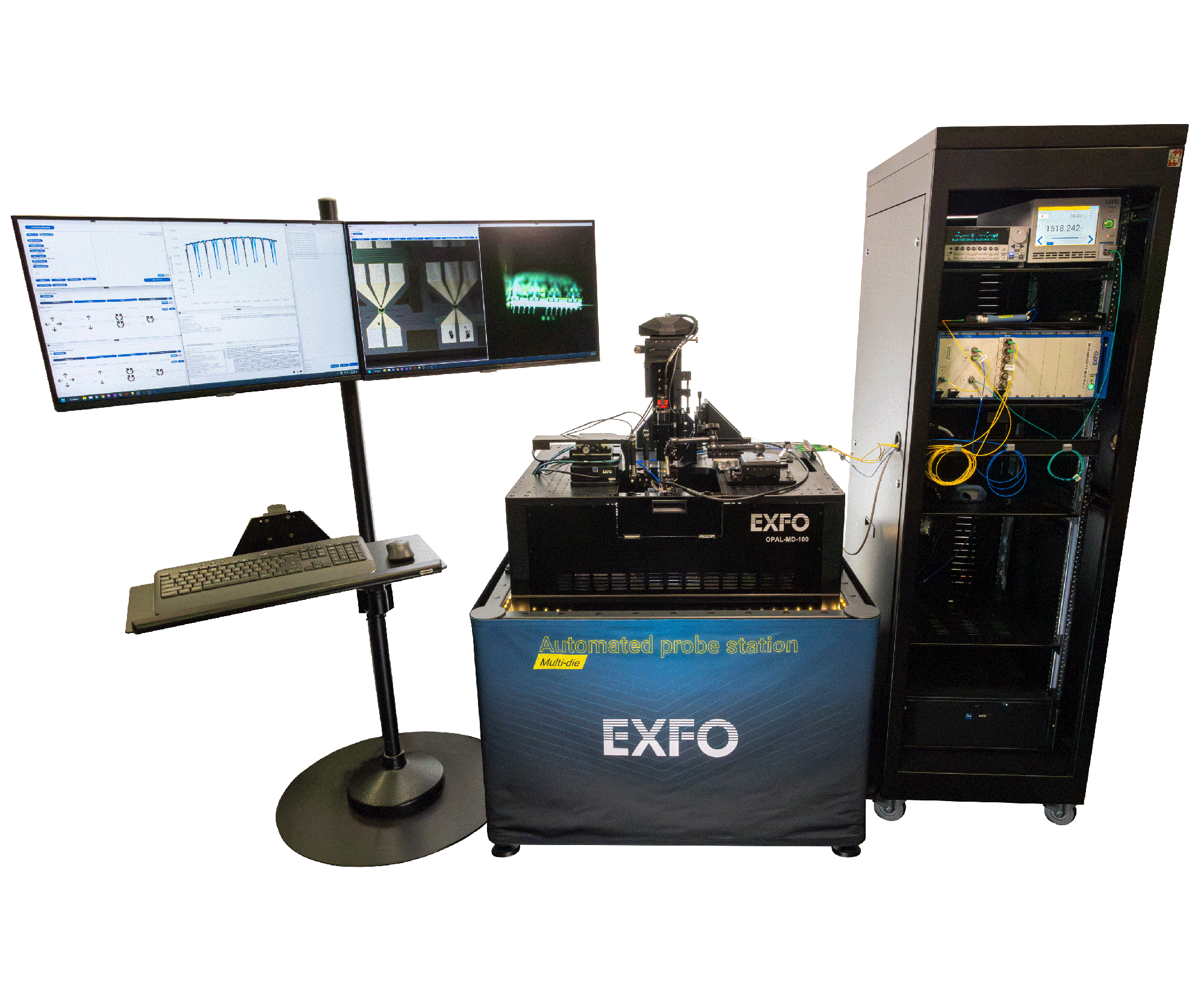

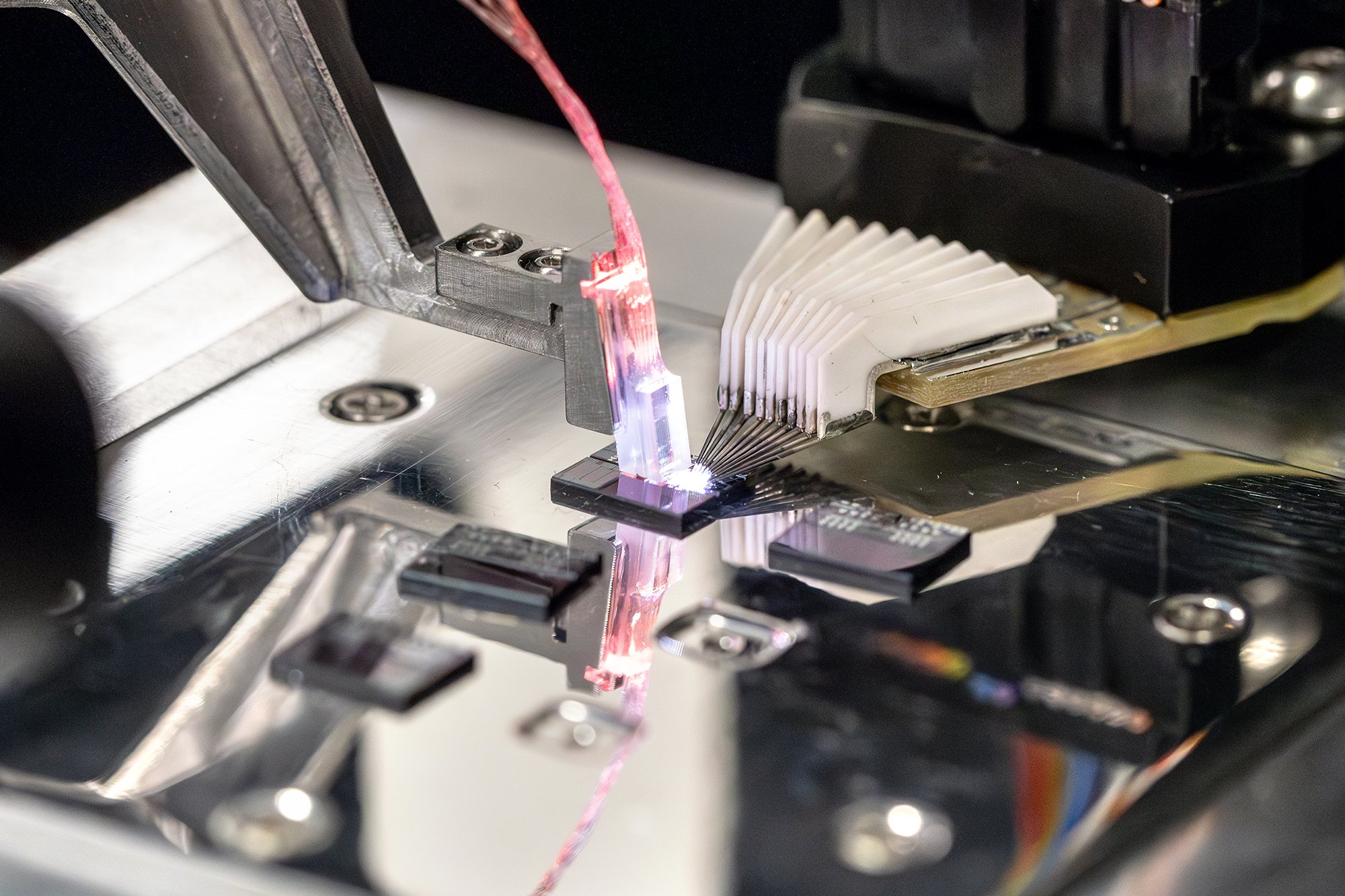

OPAL-MD – Multi-die test station - English

(March 25, 2024)

Spec sheet

OPAL-MD – Multi-die test station - Français

(March 25, 2024)

Spec sheet

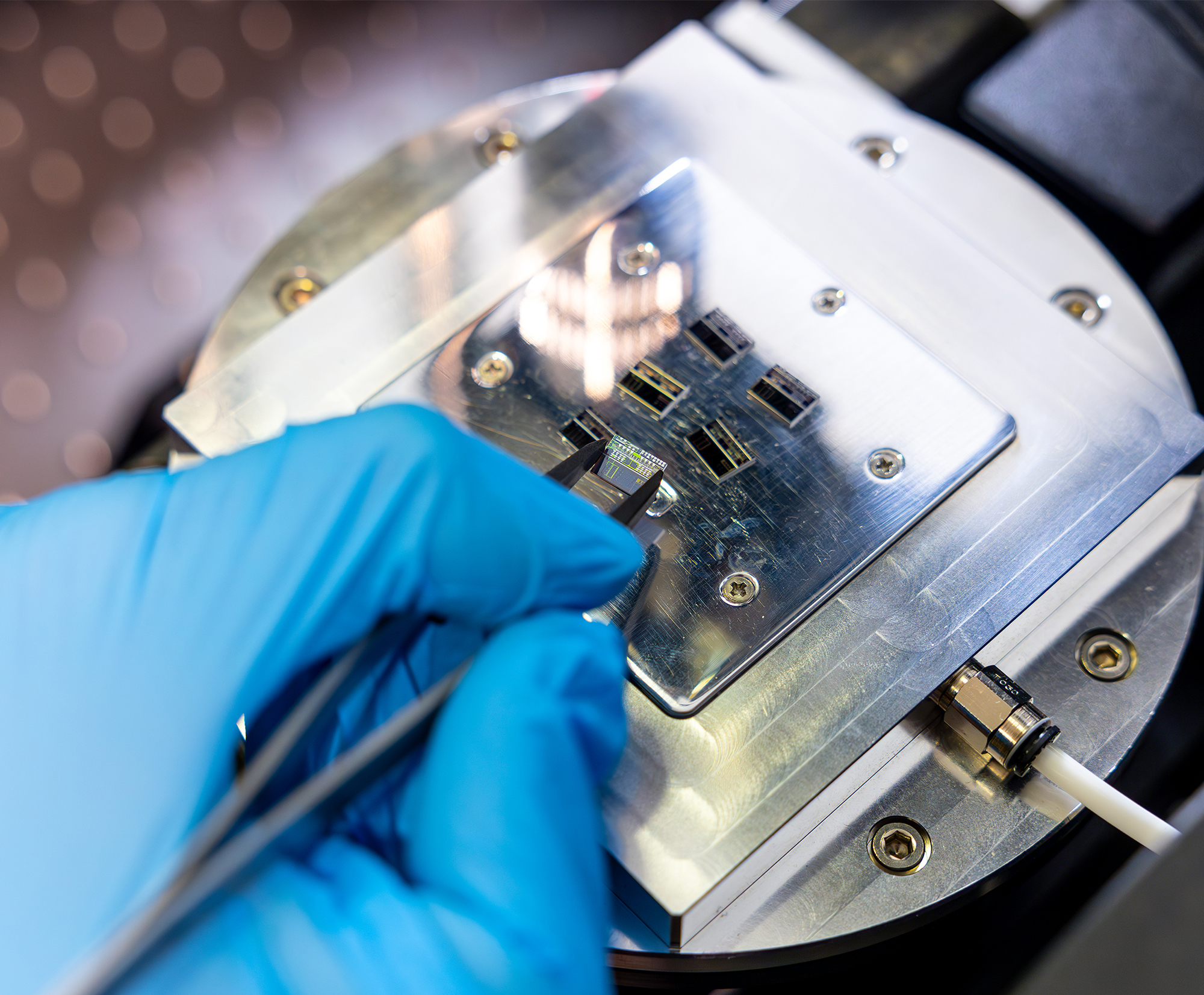

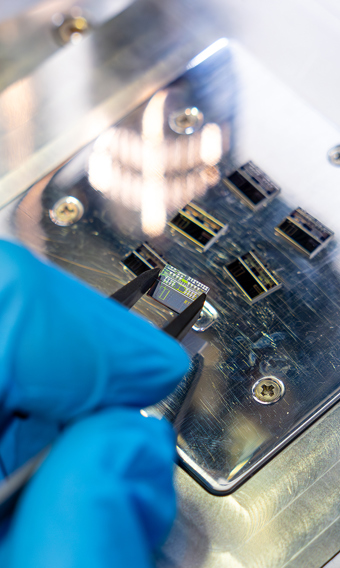

OPAL-SD – Single-die testing - English

(April 22, 2024)

Spec sheet

OPAL-SD – Single-die testing - Français

(April 22, 2024)

Spec sheet

OPAL-SD – Single-die testing - 中文

(April 22, 2024)

Spec sheet

OPAL-EC – Edge-coupling wafer-level test station - English

(November 23, 2023)

Spec sheet

OPAL-EC – Edge-coupling wafer-level test station - 中文

(November 23, 2023)

Spec sheet

OPAL-EC – Edge-coupling wafer-level test station - 日本語

(November 23, 2023)

Spec sheet

OPAL-EC – Edge-coupling wafer-level test station - Français

(November 23, 2023)

Brochures and catalogs

Optical testing solutions for universities and labs - English

(January 18, 2024)